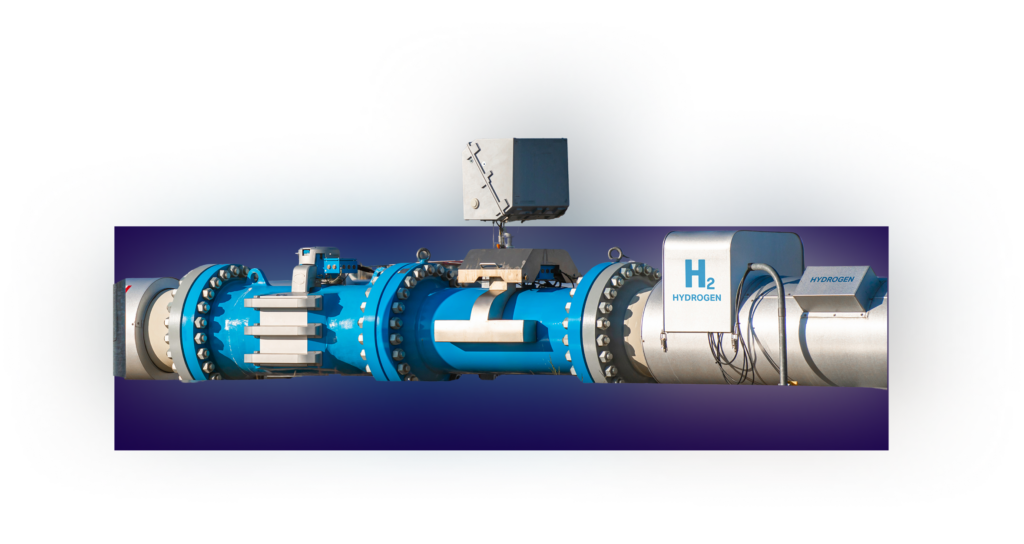

Across the steel and mining industry, momentum toward green hydrogen steel production is accelerating. Producers are running pilots for hydrogen-based DRI, hydrogen-ready burners, and hybrid-fuel smelting in partnership with technology and energy suppliers. Even though these pilots remain small in scale, they clearly show that hydrogen can support industrial-grade reduction, melting, and high-temperature operations.

But there is a critical gap — data.

Early hydrogen pilots blend hydrogen with natural gas or syngas in constantly shifting ratios. Every change in the fuel mix affects furnace chemistry, temperature stability, and the true carbon intensity of each heat or batch. To prove that a product is genuinely “low-carbon,” plants need a reliable way to link fuel-mix data to every heat, tap, batch, or coil.

Traditional MES and ERP systems were never designed for hybrid-fuel operations. As a result, plants are left with incomplete, non-auditable hydrogen-use records — a major barrier to making credible green-steel claims and passing customer or regulatory audits.

How Green Hydrogen Steel Production Alters Furnace Chemistry—and Why It Matters

Blending hydrogen into DRI, smelting, and high-temperature refining introduces new thermochemical dynamics that traditional process controls struggle to capture. In green hydrogen steel production, hydrogen behaves very differently from natural gas or coke-based fuels.

Because hydrogen has a higher reduction potential, lower molecular weight, and distinct heat-transfer properties, it changes furnace behavior in measurable ways. Even modest substitution levels can:

- alter reduction kinetics inside DRI modules

- shift oxidation patterns in smelting operations

- create new burner flame characteristics in reheating and melting furnaces

These variations impact temperature stability, metallurgical quality, and ultimately the carbon intensity of every heat.

The challenge is that conventional sensors and controls often cannot accurately monitor H₂ and H₂/H₂O ratios in real time — leaving critical process data invisible right when plants need it most.

Why MES Becomes the Backbone of Hydrogen Traceability

Introducing hydrogen into DRI, smelting, and high-temperature refining adds a level of thermochemical complexity that traditional process controls simply don’t capture. In green hydrogen steel production, most plants run pilots in hybrid mode, where hydrogen is blended with natural gas or syngas in constantly changing ratios.

As hydrogen proportions shift, reaction profiles change. These variations influence furnace temperature, process stability, metallurgical outcomes — and the true carbon footprint embedded in every heat or batch.

When a coil, billet, matte stream, or DRI batch is labelled “low-carbon,” its carbon intensity must accurately reflect the exact share of hydrogen used at the moment of production. Without granular, heat-specific fuel attribution, low-carbon claims quickly turn into estimates — and estimates are not auditable.

This is where MES becomes essential: it binds fuel data, production events, and emissions into one verifiable system of record.

Scheduling and Recipe Control in Green Hydrogen Steel Production

Hydrogen substitution requires far more than operational readiness. In green hydrogen steel production, success depends on precise production scheduling that aligns with real hydrogen availability.

Hydrogen supply — whether produced onsite, delivered through tube trailers, or generated from electrolyzers—does not always align with constant furnace demand. MES helps production teams schedule hydrogen-enabled heats strategically: routing specific melts, charges, or DRI batches to time windows when hydrogen feedstock is available. This ensures that carbon-intensity improvements are real, not theoretical

At the same time, hydrogen-enabled recipes differ from standard ones. They require adjusted burner curves, modified reduction parameters, new safety interlocks, and tailored smelting or heating trajectories. MES manages these recipe variations, ensuring that hydrogen blends are applied only to the heats designed for them. It creates an audit trail proving which recipes were used, when, and under what fuel conditions — something plants cannot achieve through manual logs or standalone control systems.

The Missing Link Between Hydrogen and Low-Carbon Certification

The ultimate requirement for green-steel customers — from automotive OEMs to construction groups — is not just that “hydrogen was used,” but that in green hydrogen steel production, it can be proven that hydrogen reduced the embedded CO₂ in each specific product. That proof depends on accurate, heat-level emissions attribution.

Hydrogen blending complicates this because emissions must be allocated proportionally to fuel contribution. MES becomes the system of record that binds fuel input, energy intensity, and process outcomes to product genealogy. By integrating with energy meters, flow meters, plant historians, and carbon calculation engines, MES converts operational data into auditable emissions records. This ensures that every slab, coil, billet, or matte batch can be accompanied by a defensible carbon intensity certificate

How DaVinci Enables This Transition

DaVinci supports hydrogen pilots through MES-level capabilities designed specifically for hybrid-fuel operations.

Its architecture can ingest fuel-mix metadata, manage hydrogen-aware recipes, synchronize production with hydrogen availability, and compute heat-level PCI in real time. It ensures that every hydrogen-assisted heat is fully traceable, and that every low-carbon claim is backed by transparent, audit-ready data.

By embedding emissions attribution directly into the production workflow, DaVinci closes the gap between hydrogen technology and carbon verification, the exact gap that prevents many steelmakers from commercializing low-carbon metal at scale.

Conclusion

The Strategic Insight: Hydrogen Makes Steel Greener, but MES Makes It Credible.

Its architecture can ingest fuel-mix metadata, manage hydrogen-aware recipes, synchronize production with hydrogen availability, and compute heat-level PCI in real time. It ensures that every hydrogen-assisted heat is fully traceable, and that every low-carbon claim is backed by transparent, audit-ready data.

Hydrogen reduces emissions.

MES ensures the world can trust the numbers.