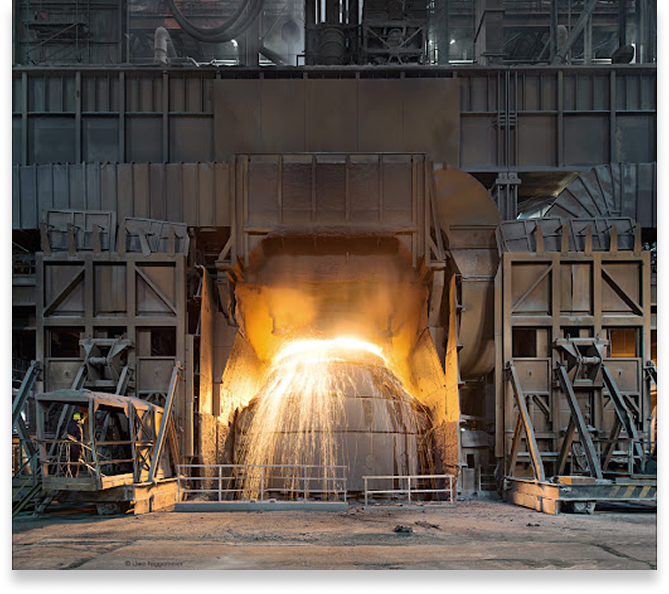

Furnace decarbonization is becoming a critical goal in the steel industry as companies strive to reduce carbon emissions and improve energy efficiency. Predictive furnace intelligence plays a key role in achieving this by monitoring temperature fluctuations, optimizing energy use, and stabilizing operations across Electric Arc Furnaces (EAF), Basic Oxygen Furnaces (BOF), Ladle Furnaces (LF), and smelting units. By leveraging real-time data and advanced analytics, furnace decarbonization can be achieved more efficiently, cutting CO₂ emissions while maintaining production quality.Decarbonizing high-temperature processes requires more than equipment upgrades. It requires a deep understanding of the thermochemical behavior inside each furnace type, a challenge that Davinci addresses with predictive AI solutions for furnace intelligence.

Electric Arc Furnace (EAF) Decarbonization Through Predictive Intelligence

The Electric Arc Furnace (EAF) is one of the most thermally dynamic units in metals production, making it a key focus for furnace decarbonization. Volatile scrap behavior, changing slag chemistry, and arc instability create variability in heat transfer, leading to energy losses from unpredictable scrap melting, inconsistent slag foaming, and arc fluctuations.

Differences in scrap density, moisture, coatings, and residual elements cause uneven heat absorption during meltdown. Because traditional control systems assume a uniform charge, operators often apply 20–40°C excess superheat to avoid temperature shortfalls, increasing energy consumption and CO₂ emissions.

Slag foaming inefficiencies caused by FeO variability, carbon reactivity, and slag viscosity expose the arc and raise kWh per ton, directly impacting steel furnace energy optimization. In addition, fluctuating oxygen-carbon reactions release exothermic heat unpredictably, making endpoint temperature control difficult.

Predictive furnace intelligence addresses these challenges by modeling arc stability, scrap melting kinetics, slag behavior, oxidation reactions, and off-gas energy in real time. This enables stable heat trajectories, reduced superheat, and improved process control.

By implementing energy optimization solutions for the steel industry, EAF operators can reduce electrical energy consumption by 3–8%, shorten tapping cycles, and cut re-melt rates by up to 40%, supporting efficient and low-carbon furnace operation.

Basic Oxygen Furnace Basic Oxygen Furnace (BOF) Decarbonization with Predictive Control

The Basic Oxygen Furnace (BOF) is driven by rapid and highly exothermic reactions, making it a critical area for furnace decarbonization. Small variations in hot metal temperature, silicon content, scrap ratio, or oxygen flow can trigger large, nonlinear changes in heat generation, increasing process variability and energy loss.

A major source of inefficiency in BOF operations is overblowing, where oxygen is injected longer than required due to uncertainty in endpoint carbon and temperature. Because it is difficult to distinguish chemical reactions from thermal changes inside the converter, operators often overshoot target temperatures. This leads to excessive downstream cooling through lime additions, scrap cooling, or reblows, all of which introduce avoidable energy penalties.

By improving endpoint predictability and controlling exothermic intensity, predictive furnace intelligence supports energy optimization solutions for the steel industry, enabling tighter temperature control, reduced overblowing, and lower energy consumption. These improvements directly contribute to more stable BOF operation and effective furnace decarbonization.

Furnace Decarbonization in Ladle Furnaces Using Predictive Intelligence

The ladle furnace is a major but often overlooked source of energy loss in steel plants, making it a critical area for furnace decarbonization. Inaccurate temperature expectations, variable ladle refractory conditions, slag carryover, and uneven heat homogenization force operators to apply 15–30°C of excess superheat at tapping to avoid temperature drops at the caster. Over thousands of heats, this practice leads to significant increases in kWh consumption and CO₂ emissions.

Slag chemistry further impacts energy efficiency, as high FeO or MnO levels create oxidizing conditions that increase alloy usage and destabilize thermal control. Predictive furnace intelligence enables steel furnace energy optimization by modeling heat losses, refractory behavior, and homogenization time to determine the optimal superheat required. This reduces unnecessary reheating, improves temperature accuracy at the caster, and supports energy optimization solutions for the steel industry, delivering 5–10% reductions in ladle furnace energy consumption and lower carbon intensity.

Non-Ferrous Smelting Furnace Optimization for Furnace Decarbonization

Non-ferrous smelting furnaces used in copper, nickel, and ferroalloy production experience high energy variability due to changes in concentrate composition, slag chemistry, oxidation-reduction reactions, and off-gas energy behavior. Small variations in sulfur content, moisture, or mineralogy can significantly alter heat release, slag viscosity, and matte formation, leading to unstable temperatures and increased energy consumption.

Traditional control systems lack real-time insight into these thermochemical changes and rely on wider operating margins, resulting in higher CO₂ emissions. Predictive furnace intelligence supports furnace decarbonization by modeling concentrate mineralogy, slag behavior, oxidation kinetics, and refractory heat loss to optimize smelting reactions. This enables energy optimization solutions for the steel and non-ferrous industry, improving temperature stability, reducing slag entrainment, enhancing matte quality, and delivering 3–6% reductions in energy usage.

Cross-Furnace Insight: Why Predictive Furnace Intelligence Matters

Across EAF, BOF, ladle furnaces, and smelting operations, the primary cause of energy inefficiency is process variability. Differences in charge materials, slag composition, exothermic reaction intensity, refractory condition, and operator decision-making lead to unstable heat curves, excess superheat, and avoidable CO₂ emissions.

Traditional automation can control equipment but cannot interpret or predict complex thermochemical and fluid-dynamic behavior inside the furnace. Predictive furnace intelligence enables furnace decarbonization by creating real-time thermodynamic models that forecast temperature evolution, reaction behavior, slag performance, heat losses, tapping readiness, and CO₂ emissions on a heat-by-heat basis. This allows plants to stabilize operations, reduce re-melts, and optimize energy use without hardware modifications.

Conclusion: Furnace-Specific Intelligence Enables Furnace Decarbonization

EAF, BOF, ladle furnaces, and non-ferrous smelting furnaces lose energy through different mechanisms, but the root cause remains the same—unmanaged thermal and chemical variability. By applying predictive furnace intelligence tailored to each furnace type, steel and smelting plants can transform uncertainty into precise thermal control.

The result is lower energy consumption per ton, improved metallurgical stability, reduced CO₂ emissions, and faster progress toward furnace decarbonization goals. In today’s metals industry, a predictable furnace is an efficient furnace—and an efficient furnace is a low-carbon furnace.

Traditional automation stabilizes the furnace but cannot interpret or predict the underlying thermochemical and fluid-dynamic behaviors. Platforms like Davinci leverage AI to forecast reactions, optimize heat curves, and reduce energy use.